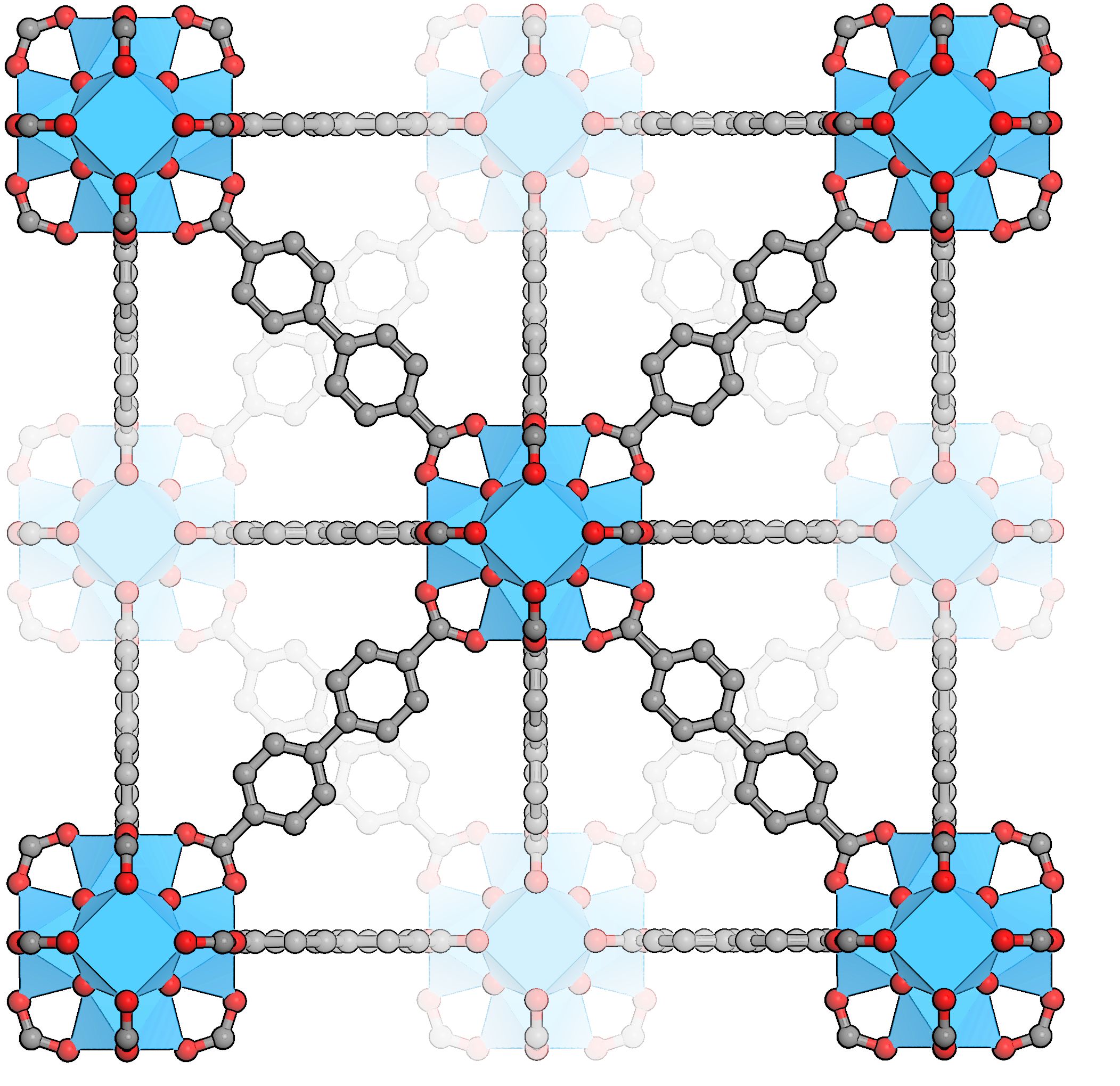

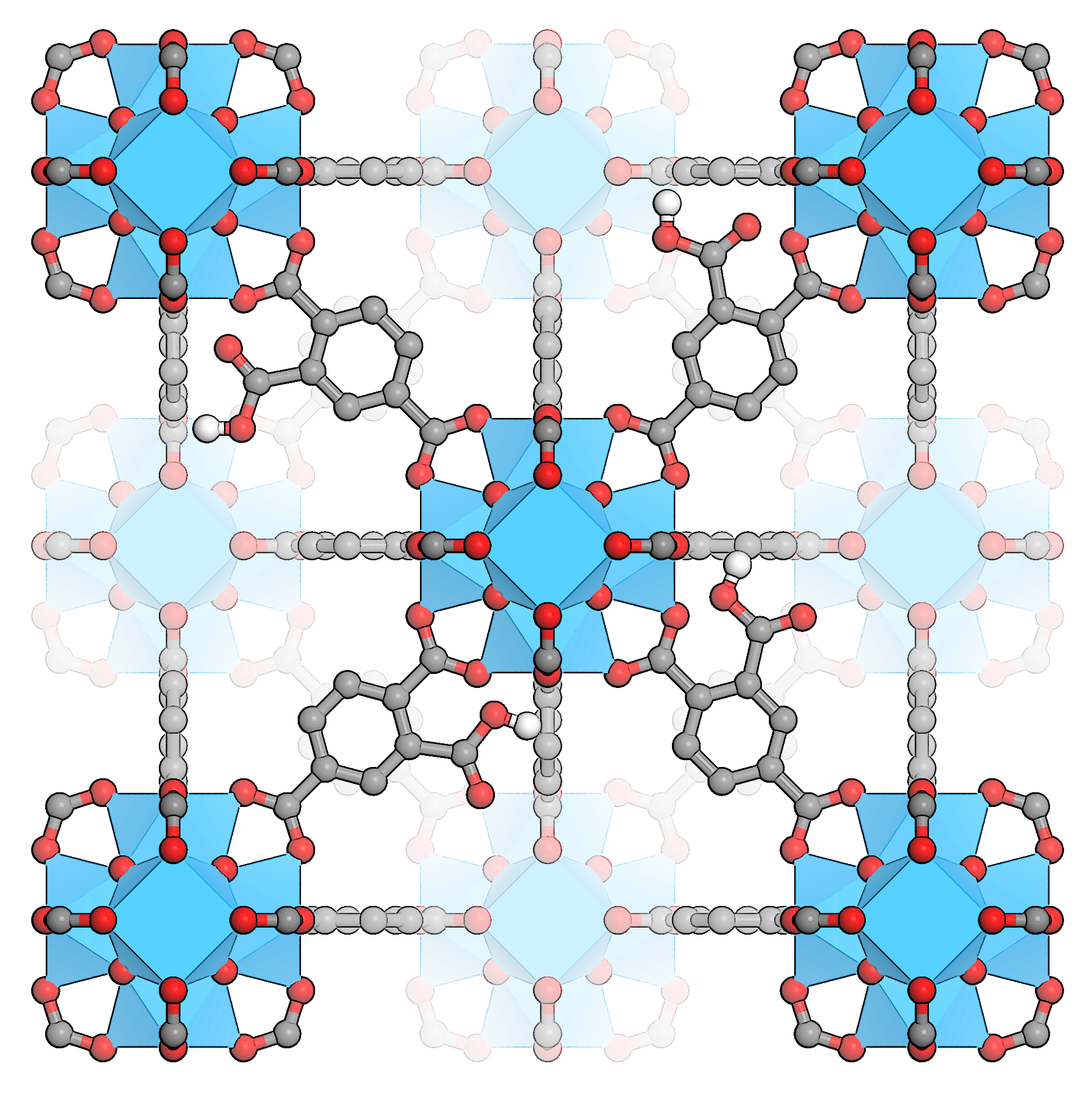

Metal Organic Frameworks (MOFs) are a relatively new class of nanotechnology materials suitable to a broad range of industrial processes.

As we continuously identify new uses and applications for Metal Organic Frameworks, testing and verification become increasingly important.

One of the largest allocations ever made by the council’s FORNY programme With over 30 applicants applying for the FORNY2020 […]

The latest and greatest within the field of MOFs ProfMOF was invited to the EuroMOF2015 conference in Berlin to present and […]